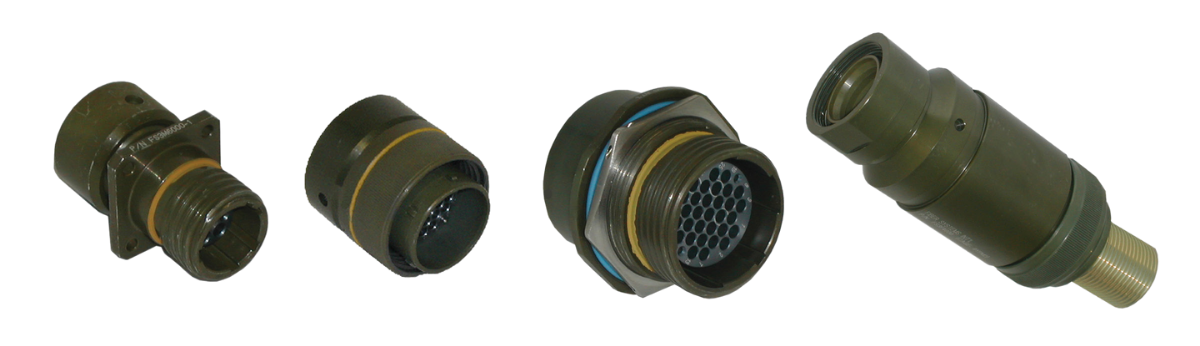

GoldRush® Fiber Optic Connectors

Physical Contact Connectors – Hermaphroditic Connectors

Amphenol Fiber Systems International (AFSI) has designed the next generation “longwall communications” deployable fiber optic connector. By responding to specific customer needs and leveraging the family of AFSI TFOCA-II® connectors, the GoldRush® series of fiber optic connectors was born. These innovative interconnect solutions have become an enabling technology for “digital mining.” AFSI’s GoldRush® connectors address specific mining requirements for the future of intelligent mining.

The GoldRush® connectors are the only Mining Safety and Health Administration (MSHA) certified fiber optic connectors for use in underground mines under Title 30 CFR, Part 18.

The heart of the GoldRush® family of deployable fiber optic connectors is the TFOCA-II® termini, featuring “sealed” free floating termini. This revolutionary design enables GoldRush® connectors to seal against high humidity and moisture conditions while allowing full axial and orbital movement of the mated termini, providing the lowest possible insertion loss.

Features

- Hermaphroditic design for versatility enables the GoldRush® plug to be daisy-chained or unreeled from either end of a reel

- Brass construction eliminates thermite concerns. Also available in stainless steel (for corrosive environments) and aluminum

- 4-channel connector design provides system flexibility

- Optional key positions – four key positions (1, 2, 3 and universal) available, enabling segregation of mated plug/receptacles or plug/plug, through mechanical interface

- Improved cable retention strength is designed to meet 400 lb pull strength while protecting fibers from stress

- Solid core alignment sleeves are more robust than split alignment sleeves

- Removable end cap allows for easy field repair and cleaning

- Commercial ceramic ferrule technology – enables GoldRush® connectors to provision multimode and single mode interconnect with a variety of polishes including SPC and UPC

- Field repairable using existing parts – additional connector components (other than termini) are not required to perform field repair

Applications

- Mining

- Oil, gas and geoscience industries

- Industrial

Certifications

- Mining, safety and health administration certification no. 18-NXA050001-0

Specifications

| Description | Measurement/Detail |

| Insertion loss (multimode) | Typical – 0.30dB, maximum – 0.75dB |

| Insertion loss (single mode) | Typical – 0.40dB, maximum – 0.75dB |

| Back reflection (single mode-PC polish) | Typical – -50dB, maximum – -40dB |

| Back reflection (single mode-UPC polish) | Typical – -50dB, maximum – -40dB |

| Operating temperature | -46° C to + 71° C |

| Storage temperature | -52° C to + 85° C |

| Mud | Five minute immersion, clean with water |

| Water pressure | One meter for 24 hours |

| Ice crush/freezing water | Immersed and frozen in water for seven hours |

| Humidity immersion | TIA/EIA-455-5, 5 cycles |

| Vibration (operational) | TIA/EIA-455-11 |

| Shock | EIA/TIA-455-14, Condition A |

| Cable seal flexing | 100 cycles per TIA/EIA-455-1 |

| Twist | 1,000 cycles per EIA/TIA-455-36 |

| Cable retention | 400 lb minimum per EIA/TIA-455-6 (applies to plug only) |

| Impact | EIA/TIA-455-2 |

| Crush resistance | 450 lb minimum per EIA/TIA-455-26 |

| EMI shielding effectiveness (receptacle only) | > 60dB |