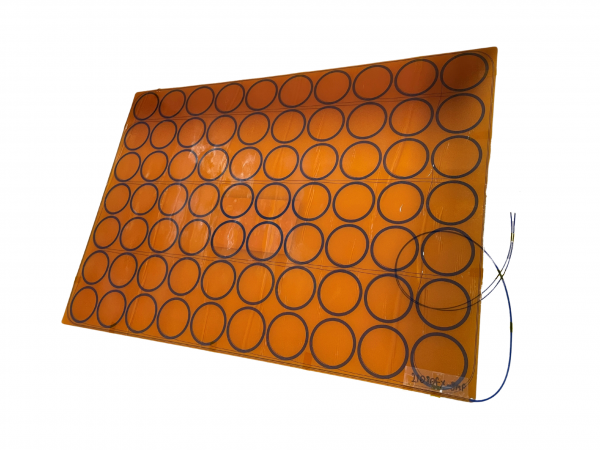

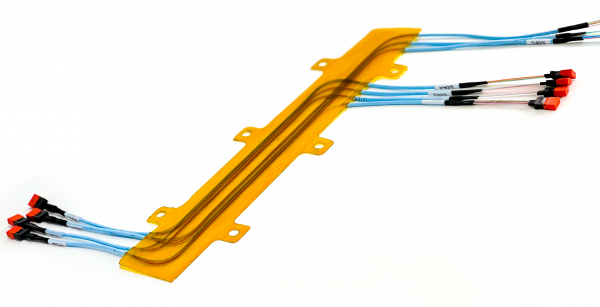

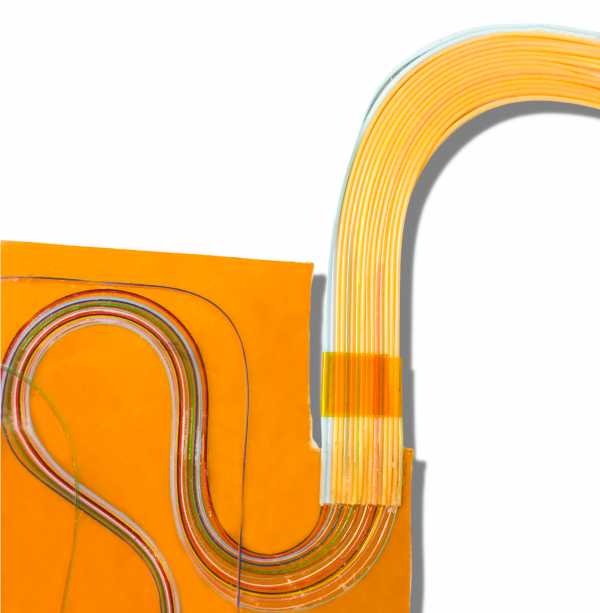

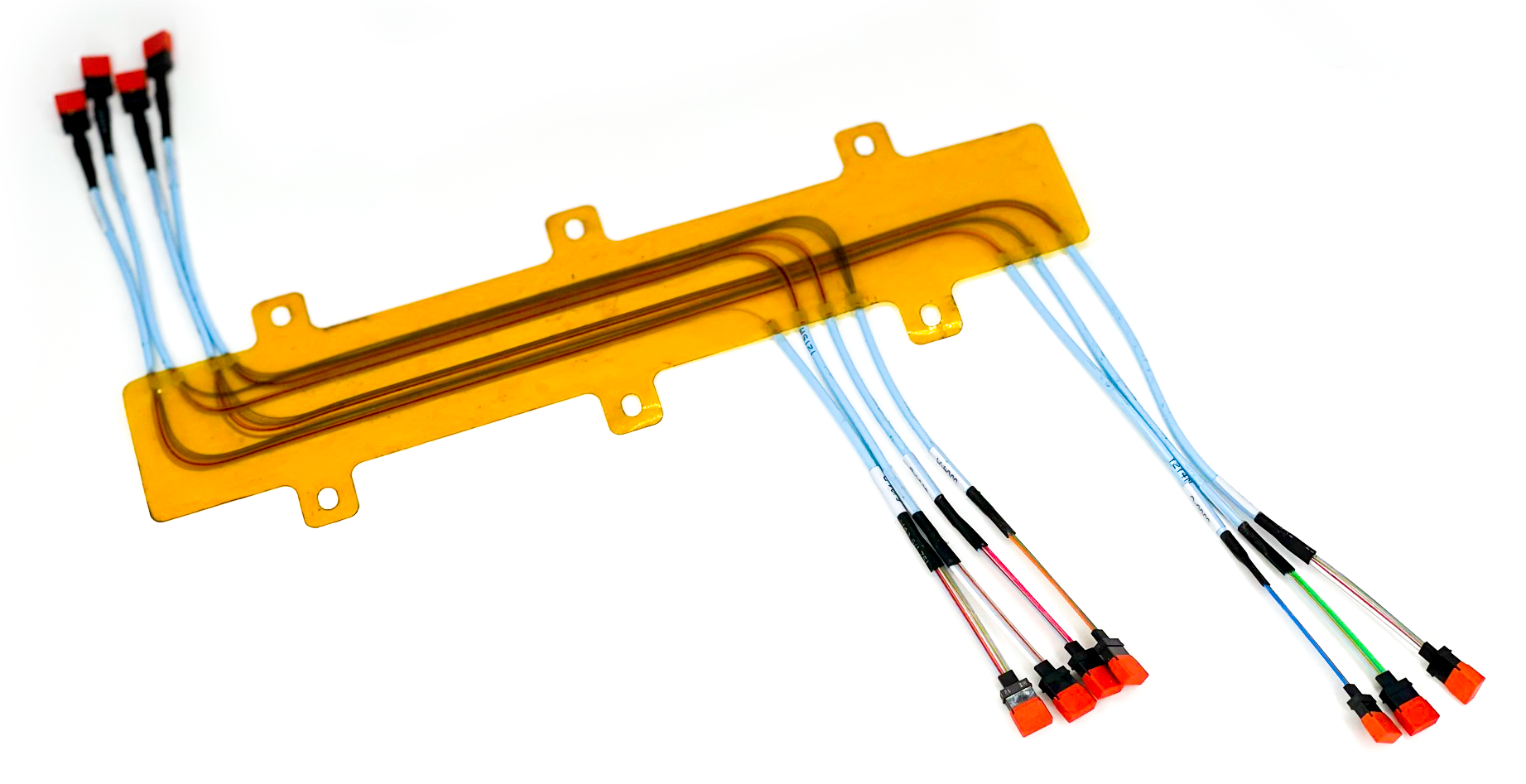

Amphenol FSI’s Fiber Flex optical backplanes respond to the increasingly present requirement for wire and cable management to maximize airflow inside LRUs and communication systems. Fiber Flex planes provide a manageable method of routing fiber from interface to interface and from shelf-to-shelf. Designed for versatility, standard Fiber Flex circuitry provides high-density routing on a flexible, flame-resistant substrate.

Fiber Optic sub-systems often need to be quickly diagnosed and replaced on backplanes without disrupting the entire LRU. Design flexibility is a key element to simplify system architect’s need to meet the particular demands of each application. Available in virtually any routing scheme, fiber can be routed point-to-point, in a shuffle or in a set pattern to meet specific application requirements. Direct or fusion-spliced terminations are available, input and outputs to ribbon, discrete are easily integrated in the design along with any mix of fiber sizes.