F-143

Fiber Optic Connectors

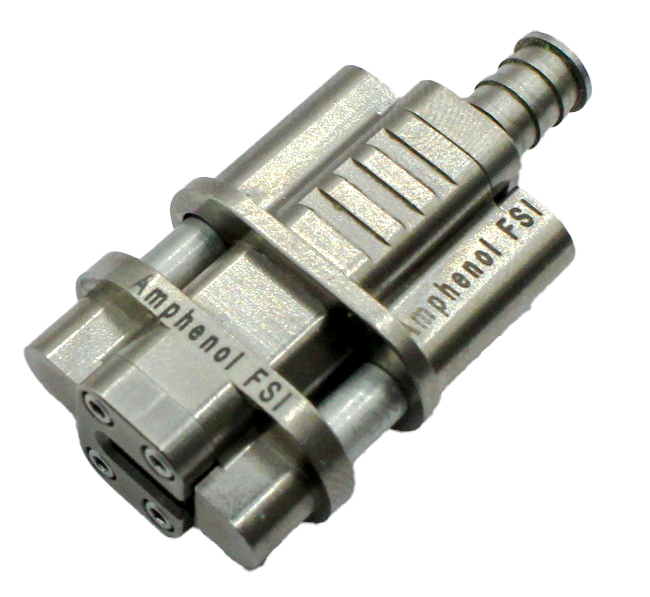

Amphenol Fiber Systems International (AFSI) manufactures a complete line of next generation circular fiber optic connectors designed to meet the needs of harsh environment applications. Building on the legacy of MIL-PRF-28876, Rev. E these connectors incorporate the latest technologies in fiber optic interconnect design. These connectors are precision machined to stringent tolerances and designed to provide superior optical performance in extreme environmental conditions.

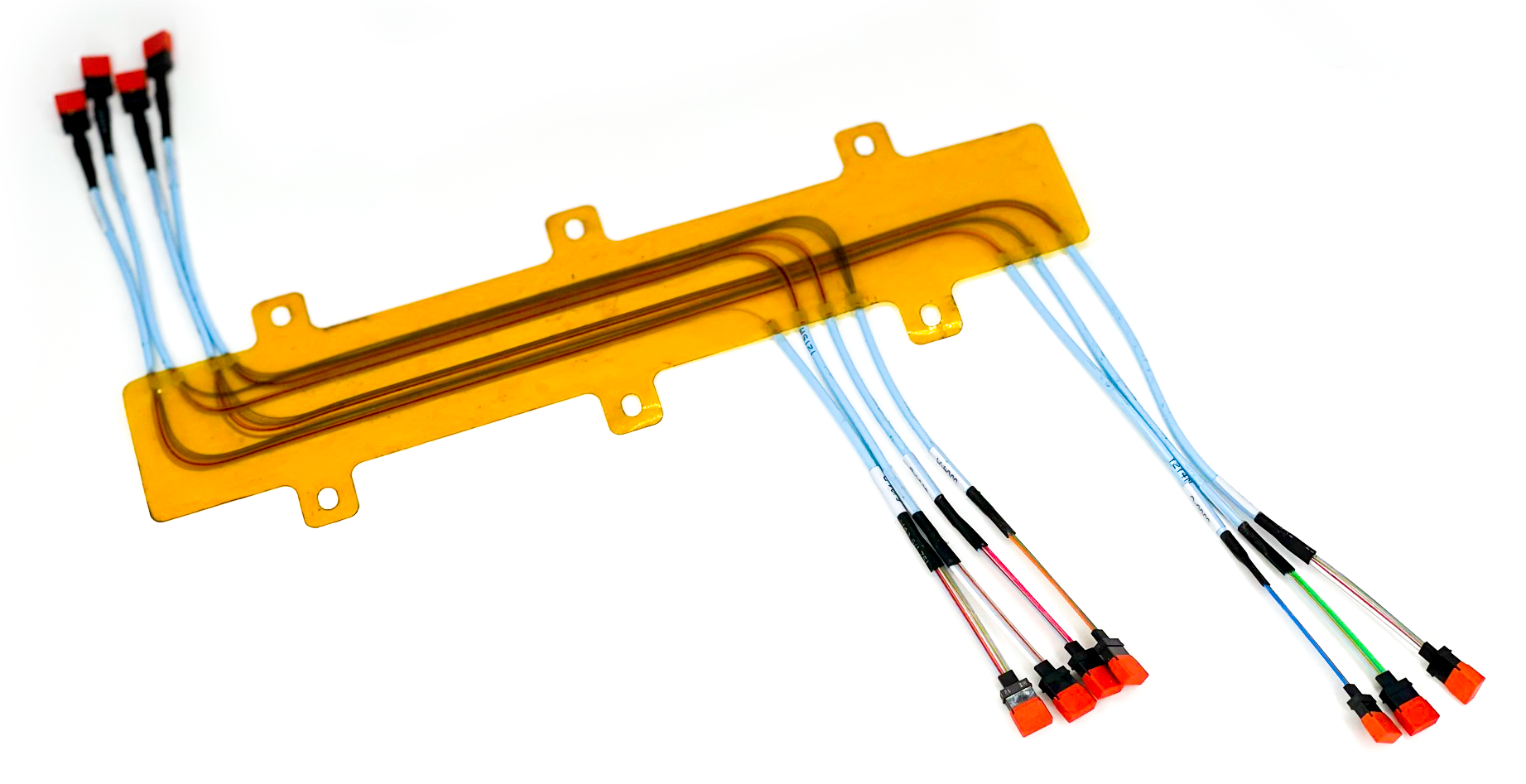

The backshells feature the Quickloc™ captivation system developed by Amphenol Fiber Systems International. Not only is it simple to install, it is also easy to remove the captivated aramid yarn of the cable and recapture without cutting back the cable. The Quickloc™ backshell also allows easy access to maintain or reconfigure termini without altering the captivated aramid fiber.

Features & Benefits

- Precision machined metal housings and inserts

- Available in 3 shell sizes: 13 (4 ch), 15 (6, 8 ch), 23 (18, 31 ch)

- Ergonomic, Ratcheting, Anti-vibration coupling nut

- A complete suite of backshells is available to provide environmental sealing

- Multiple Key Options

- Alignment Sleeves Retainer (ASR) assembly can be removed without disassembly of the connector

- Removable ASR can be configured on plug or receptacle

- Genderless, front release termini with integral retaining clip and seal

- Complete line of straight, 45 degree and 90 degree backshells

- Al Alloy, Marine Bronze and SS316 versions available

- Superior optical performance with an easy to clean and maintain removable Alignment Sleeve Retainer (ASR)

- Backshell design allows simplified, removable aramid yarn captivation with no mechanical crimp rings

- “Arctic” style coupling nut resists loosening from vibration

- Angled backshells use the same tools as the straight backshell

- Quickloc™ design enables faster maintenance or repair without complete disassembly of connector backshell assembly

Applications

- Shipboard, surface craft and submarines

- Offshore Oil and Gas Platforms and Drillships

- Mobile tactical shelters electronic battlefield networks

- Mobile Emergency Telecommunications (MET) stations

- Deployable outdoors in harsh environments

Specifications

| Description | Measurement/Detail |

Mating Durability |

1000 cycles per EIA-455-21 |

Vibration |

Per MIL-STD-1344, Method 2005, Condition II & VI |

Mechanical Shock |

Per MIL-STD 901C Grade A |

Thermal Shock |

-54°C to +65°C per MIL-STD-1344, Method 1003 |

Thermal Cycling |

-62°C to +70°C per MIL-STD-1344, Method 1003 |

Corrosion Resistance |

500 hour salt spray MIL-STD-1344, Method 1001 |

Ozone Exposure |

Per MIL-STD-1344, Method 1007 |

Humidity |

10 cycles per MIL-STD-1678, Method 4030 |

Fluid Immersion |

Per MIL-STD-1344, Method 1016 |

Crush Resistance |

7 tests @ 1250 Newton per MIL-STD-1344, Method 2008.1 |

Maintenance Aging |

Per MIL-STD-1344, Method 2002 |

Terminus Retention Force |

22 lbs. min. per MIL-STD-1344, Method 2007 |

Insert Retention Axial |

100 PSI min. per MIL-STD-1344, Method 2010 |

Cable Pull Out Force |

162 pounds min. per EIA-455-6 |

Cable Sealing Flexing |

Per MIL-STD-1344, Method 2017 |

Impact |

Per MIL-STD-1344, Method 2015 |

Flammability |

Per MIL-STD-1344, Method 1012 |

Operating Temperature |

-54°C to +65°C |

Storage Temperature |

-62°C to +70°C |

Typical Insertion Loss |

0.4 dB Nominal Multimode, 0.5 dB Nominal Single mode |

Connector Insert |

Aluminum Alloy, Anodized |

Connector, Backshells and Dust Cover |

Aluminum Alloy, CAD Plate, 316L Stainless Steel, Marine Bronze |

Cable Sealing Strain Relief |

Polyolefin, Self Encapsulating |